CNC milling, turning and EDM, band cutting and 3D printing

We have a comprehensively equipped machine park with modern numerically controlled machine tools. We can take on any challenge in the field of the mechanical processing of materials and perform it at the highest technical level.

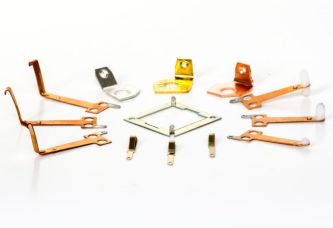

We specialise in the processing of plastics and metals. We process stainless steels, aluminium, tungsten, brass and many other materials. We employ high-class specialists in the field of machining and programming of CNC machine tools. We provide efficient and precise production.

CNC milling

Our machine park:

- enables work with materials such as: steel, aluminium, copper and other non-ferrous metal alloys and plastics;

- is equipped with a device with a working area (X-700, Y-600, Z-270 mm), which enables the processing of both small details and products with complex shapes;

- allows for the processing of, among others, machine elements, the construction of plastic products and dies.

CNC turning

Our machine park:

- enables work with materials such as: steel, stainless steel, non-ferrous metals, cast iron, aluminium and plastics;

- provides the following parameters:

- turning diameter over bed: 500 mm,

- turning diameter over support: 250 mm,

- maximum element length: 1000 mm.

CNC EDM

Our machine park:

- allows us to work with various metal materials, in particular with such demanding materials as: sinters, tungsten and its alloys;

- is equipped with a device with a working area (X-630, Y-500), which enables the processing of small and medium-sized details;

- allows for the processing of, among others, machine parts and elements made of tungsten.

Band cutting

Our machine park:

- allows to work with materials such as metals, plastics, wood;

- device working area (X-500, Y-400);

- height of the cut element max. 160 mm;

- the possibility of cutting at an angle;

- example projects include the elements of plastic products, the construction elements of machines, etc.

3D printing

Our machine park:

- enables 3D printing from plastic (work in the FDM technology);

- is equipped with a machine with a working area (X-300, Y-300, Z-300 mm), which enables the printing of various details;

- allows us to make prototypes and low-volume production.