Welding of non-ferrous metals

The improved production technologies allow us to achieve high efficiency in welding / brazing precise elements made of various non-ferrous metals.

Welded elements are increasingly replacing traditional crimped and twisted joints from the market. Thanks to the elimination of additional materials (cable terminals, solders), we are able to reduce significantly the price of electrical joints.

The basic advantages of welded joints include:

- low production costs (speed of operation),

- no additional materials,

- high durability of the joint,

- very good electrical parameters (low resistance).

The developed technologies allow to combine components made of various materials, such as:

- aluminium,

- copper,

- brass,

- nickel,

- bronze.

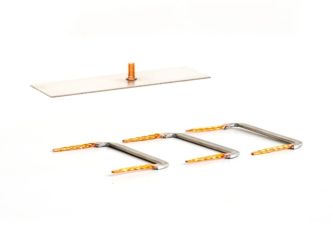

We also offer the service of welding the pre-briquetted copper cords, braids and cables with other materials, for example with terminals, steel casings, copper and brass flat bars.

Compacting (briquetting) of cords

For joints exposed to work in particularly difficult conditions, we suggest using binders with an admixture of silver, which further improve the mechanical parameters (joint durability) and electrical parameters of the weld. It is also possible to form eyelets from own material on the cords.

Both resistance welding and compacting technologies have been recognised in such demanding industries as: automotive, household appliances, energy, power tools, electro-mobility or the photovoltaic cell industry, where they are replacing increasingly the traditional types of permanent electrical joints.

We guarantee the high durability of the created joints and very small voltage drops between the welded elements.